Rapidly growing demand for data capacity means that data centre power requirements are increasingly reaching megawatt rather than kilowatt levels. In this article, Kenny Green, Technical Support Manager at KOHLER Uninterruptible Power, a KOHLER company looks at how UPS providers can respond to this challenge while maintaining the availability and energy efficiency standards enjoyed by lower power installations.

Data centres are getting larger, sometimes dramatically so. In Langfang, China, construction is under way at the Range International Information Hub. When completed in 2016, this commercial data centre will become probably the largest in the world; covering 6.3 Million square feet, it will be nearly the same size as the Pentagon. Other data centres of a million square feet or more are already in existence across the US and other parts of the world.

Although these extremes are unusual, they reflect the growing trend for larger-scale processing facilities for enterprises of all types and sizes. We all increasingly rely on our Smart devices and computers for our transactions, searches for information and socialising, while the last two or three years have also seen rapid growth in machine to machine (M2M) communications. According to a market research report published by MarketsandMarkets, the automotive and transportation data communication sector has the highest projected growth, with a CAGR of 33.5% from 2012 to 2017.

As enterprises gear their data centres to accommodate the capacity demand generated by these factors, they find that their power demand is increasingly being reckoned in megawatts rather than tens or hundreds of kilowatts. As these larger facilities come on line, their users have an even greater need for energy efficiency, green operation, availability and flexible scalability than smaller operations do; the consequences of underperformance or failure grow as the data processing load grows.

Uninterruptible power supply (UPS) vendors are increasingly able to meet these larger requirements, by scaling their technology as required. One powerful approach is based on transformerless modular UPSs; while kilowatt-level modular systems have been widely established for many years, megawatt implementations have now become possible. We can see how UPS installations of all sizes can achieve the benefits they need by taking a closer look at the technology now available across all levels of power requirement.

Significantly increased energy efficiency – and significantly reduced size and weight

When on line UPSs first became popular in the Seventies, their design used an internal step-up transformer. These have remained popular for many years, especially for larger systems. However the industry has more recently moved towards transformerless technology because, as we shall see, doing so offers many advantages.

Transformerless topology has become viable through advances in power semiconductors and the appearance of the Insulated Gate Bipolar Transistor (IGBT). This has allowed UPS designs in which the DC level supplied to the output inverter is boosted; the AC output from the inverter is correspondingly higher, eliminating the need for the step-up output transformer that previously followed the inverter.

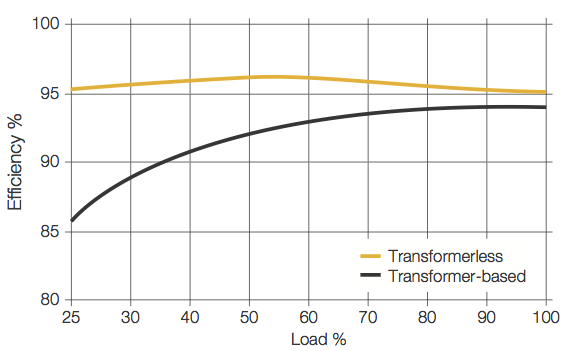

Eliminating the transformer has a significant impact on the UPS’s overall efficiency; as Fig. 1 shows, this increases by around 5% to yield a substantial reduction in energy running costs and heat losses. We can also see that the transformerless efficiency curve remains flat for loads from 25% to 100%, while transformer-based UPS efficiency drops away steadily as loading decreases from 100%.

Fig. 1: UPS ac-ac efficiency curves for transformerless and transformer-based topologies

Further efficiency savings arise due to power factor improvements. The transformer-based systems present a lagging power factor to the incoming supply, which is well below unity at full load, and decreases further with decreasing load. By contrast, transformerless UPSs present a full-load input power factor which is much closer to unity and remains load-independent. Total Harmonic Distortion (THDi) is reduced from around 30% to around 3%, virtually eliminating harmonic pollution of the incoming mains supply. Overall, the magnitude of the input currents is reduced, which in turn minimises the sizes of the cabling and switchgear, and in some circumstances reduces electricity running costs.

Transformerless technology’s contribution to energy saving is matched by the substantial saving in size and weight it provides. This is because transformerless systems not only eliminate the transformer, but also operate with a much smaller rectifier. For example a 120kVA transformer-based UPS has a footprint of 1.32 m2 and weighs 1200 kg, while its 120kVA transformerless alternative has a footprint of 0.64 m2 and weighs just 310 kg.

These physical factors have had a profound effect on UPS development, as they are sufficient to allow UPS units of up to 100kVA to be implemented as rack-mounting modules instead of cumbersome standalone systems. This brings major benefits in terms of parallel redundancy, right sizing and extensive scalability. These are in addition to the efficiency, energy saving and reduced cooling costs provided by the underlying transformerless topology.

Modular scalability benefits – a practical example

KOHLER Uninterruptible Power, a KOHLER company, has recently introduced their latest modular three-phase UPS system – The PW 9500DPA. This exhibits all the benefits of modular topology on a system that scales from 100kW to 3MW, taking users up into megawatt power levels when their circumstances demand it. In this example, ‘W’ equates approximately to ‘VA’ as the UPS power factor is close to unity.

PW 9500DPA starts with a single frame which can accept up to five UPS modules, each rated at 100kW. Therefore the UPS could be populated with one module to support a 100kW load, then more modules can be added, incrementing the UPS capacity in 100kW steps to keep pace with its growing critical load. This process is known as ‘Vertical Scalability’. If the load then grows beyond 500kW, up to six frames can be paralleled to achieve a total capacity of 3MW. This second dimension of expansion is known as ‘Horizontal Scalability’.

Achieving the highest possible power availability is essential to any UPS installation – ultimately, it’s the only reason for investing in a UPS at all. The PW 9500DPA delivers an availability of 99.9999% (Six Nines) by minimise the mean time to repair (MTTR).

For example that the UPS has to support a 400kW load. When fully populated, a single PW 9500DPA frame has five 100kW modules, which share the 400kW load during normal operation. If any single module fails, the remaining four can continue to fully support the load. Known as N+1 redundancy, this arrangement can improve the system availability

If a module does fail, the PW 9500DPA’s ‘Hot Swap’ capability allows the faulty module to be removed and replaced, without need to power down the UPS. MTTR is minimised, availability is maximised, and power to the load continues without interruption.

PW 9500DPA – megawatt-level power with high availability and high efficiency

The PW 9500DPA UPS is ideally suited to megawatt-level critical loads, because it offers the availability levels essential to such installations, while also addressing their need to minimise energy and cooling costs. Its true online efficiency is 96%, which can be increased to 99% in Eco-mode operation. Capital expenditure and space requirements are also minimised, as its power capacity can be closely matched to the critical load size, even if this changes.