Caught between a growing dependence on IT resources and a heightened concern over power grid reliability, organisations increasingly regard uninterruptible power supplies as critical components of their IT infrastructure. UPS insatllations, however, call for a significant level of investment, so it is important to understand the true costs of UPS ownership and the factors that impact the total cost of ownership.

In this article, Kenny Green, Technical Support Manager at KOHLER Uninterruptible Power (KUP), a KOHLER company, discusses these issues and shows how UPS costs can be mitigated by using modular UPS systems technology.

UPS cost factors

An early decision in the selection process concerns the UPS topology; should it be a traditional transformer-based type or an modular UPS installation? A traditional uninterruptible power supply may have a lower initial purchase price, but costs more to operate than a modular UPS solution for several reasons. These higher costs start even before UPS installation, with a transformer-based UPS solution being considerably larger and heavier than its modular equivalent, meaning transportation costs will be significantly higher.

This trend continues after delivery depending on the UPS installation configuration costs for the traditional system can be higher. It can also occupy a greater area of valuable floor space, which could be used for revenue generating server racks. During operation, its original cost advantage is further eroded, and then reversed, due to its lower efficiency and higher cooling requirement. Other, indirect factors also contribute; these include maintenance of UPS systems, training for UPS maintenance, and spare part holding.

The modular UPS system’s superior commercial appeal is extended if capacity expansion is ever required. If this is the case, modularity makes a uninterruptible power supply far easier and less costly to upgrade. While offering all these cost benefits, the modular approach also better justifies the reason for a UPS installation at all, as it significantly improves the uninterruptible power supply’s availability.

Scoping the costs

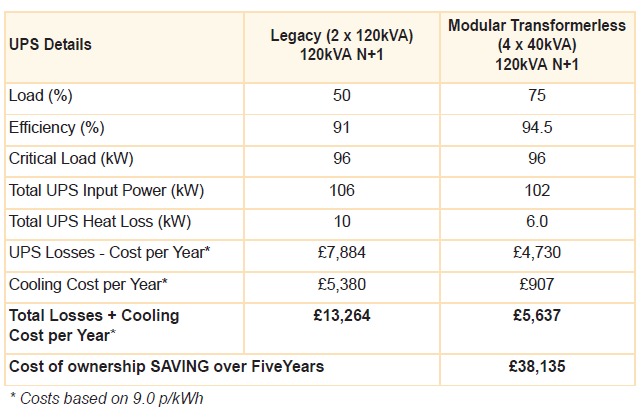

A modular UPS system’s extra initial purchase cost can be recovered within the first year of operation because of its improved efficiency. The example in Fig. 1 below shows how this is possible. Other factors are then discussed, showing how they further reduce the relative cost of owning a modular UPS system.

The example compares the traditional and modular UPS systems’ cost of ownership arising from efficiency and cooling losses over a five year period. Both uninterruptible power supplies support a load of 96kW, which equates to 120kVA at a power factor of 0.8. The traditional or legacy UPS installation comprises two 120kVA modules operating in a 120kVA N+N redundant configuration. The modular UPS system also provides redundancy in a N+1 configuration, using four 40kVA modules to cover the load.

Fig. 1: Heat loss and cooling costs for traditional and modular UPS systems

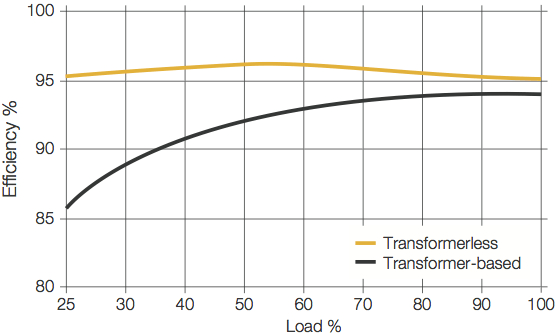

These figures show how modular UPS system efficiency is better than that of a traditional, transformer-based uninterruptible power supply. This is partly because a modular UPS system’s transformerless technology is simply more efficient, but it is mainly due to the difficulty of ‘right sizing’ a monolithic traditional UPS power suuply. In the example, the system is only 50% loaded, which reduces its efficiency significantly. Fig.2 shows the relative efficiencies and effects of loading for the two UPS technologies.

Fig. 2: UPS efficiency curve

As mentioned above, as well as having lower, more load-dependent efficiencies, transformer-based UPS power supplies are considerably larger and heavier than their transformerless UPS equivalents. For example, an 80kVA transformer-based UPS power supply unit weighs approximately 1150 kg with a volume of 1.3 m3. Two uninterruptible power supply units used for an 80kVA N+N system would, therefore, weigh 2300 kg in total, and occupy 2.6 m3. By comparison, an 80kVA N+1 modular UPS system, built with three 40kVA modules in a single rack, weighs around 379 kg and occupies 1.15 m3. These differences have a sizeable impact on transportation costs, which are approximately 2.26 times more for the transformer-based UPS system.

UPS installation costs are similarly affected. A traditional uninterruptible power supply, based on two units, needs two or three times more floor space than a modular type. The transformer-based version of the 80kVA N+N system specified above would need 1.44m2 floor space, while just 0.58 m2 is needed for the modular equivalent. UPS installation cost would be 86% higher for the transformer-based UPS power supply. An added advantage for the modular UPS solution is that it delivers nearly twice the power density – 206kVA/m2 compared with 111kVA/m2.

To be complete and accurate, calculations of UPS ownership costs should include provision for repair and UPS maintenance. Monolithic, transformer-based uninterruptible power supplies present logistics challenges because a failure must be identified down to component level by working on the UPS power supply while it is still in situ. This is problematic primarily because it denies UPS availability to the critical load for an extended period, but it causes other problems too. Technicians must be highly-trained to perform the depth of diagnostics needed, and specifying a spare part set which is adequate yet cost-effective is challenging. Managing these stock kits also consumes resources.

Modular UPS systems allow for faster, easier and lower-cost repairs. Spares logistic complexity reduces to holding a single module type that can be used even to support UPSs of varying power ranges. With ‘hot-swappable’ UPS modules engineers can make repairs within 15 minutes, without needing training in a wide range of different uninterruptible power supplies. The UPS power supply remains on line, while the module can be repaired without pressure off site. This approach allows up to 50% savings on stock management and logistics costs.

UPS batteries must be included in budgeting for both UPS types, as they have finite working lives and will eventually need replacing. Additionally, a budget must be allowed for removal and safe, legal and certified disposal of UPS systems as batteries are classified as hazardous waste.

Easy upgrades and optimised UPS availability

With increasing pressure and dependence on IT capacity, UPS planning should provide for future upgrades. For traditional UPS power supplies, these mean extra space and costly cabling, with the system taken off-line during the work. A modular UPS system eliminates these delays and costs because it comprises a rack containing a set of plug-in modules that can easily be replaced to meet growing critical load requirements. Extra capacity can be achieved simply by swapping, say, three 20kVA modules for three 30kVA versions. Provided the UPS’s frame and associated cabling distribution is adequate, this upgrade requires little time or cost, no extra floor space requirement and no interruption to the load.

This article has to show the factors to consider when calculating a UPS system’s true cost of ownership. It also reveals why an advanced modular UPS system ultimately costs less to own than a transformer-based equivalent, even if its initial purchase price is higher. Additionally, it’s worth remembering that as well as these costs savings, the modular topology wins on the most fundamental expectation of a UPS – its availability. Hot-swappable modules as described cuts Mean Time To Repair (MTTR) from 6 hours to 30 minutes, so modular systems make availability of 0.999999 (Six Nines) a reality.

For more information regarding any of our UPS power supply products or services, you can get in touch with KOHLER Uninterruptible Power via our contact page or call us on +65 6302 0702.