Uninterruptible Power Supply (UPS) systems are essential components to safeguard against potential power disruptions and data loss and to ensure continuity in critical business applications. However, the reliability of a UPS system heavily depends on regular and proactive maintenance to ensure these systems perform optimally and for maximum lifespan. Neglecting UPS maintenance can lead to system failure, resulting in unexpected downtime that could jeopardise safe building evacuations and put lives at risk. This article explores the recommended frequency of UPS system maintenance, the key components that require regular checks and the practices that should be incorporated into a UPS maintenance routine.

Why Regular UPS Maintenance is Essential

A UPS system’s primary function is to provide emergency power during a mains electricity disturbance, allowing for the safe shutdown of equipment or continued operation until backup generators kick in. However, like all sophisticated machinery, a UPS can develop issues over time that can compromise its effectiveness. There are regulations that need to be followed to ensure that electrical equipment is maintained. Regular maintenance is also essential to:

- Ensure operational reliability: Prevent unexpected failures during power outages.

- Extend equipment lifespan: Reduce the likelihood of premature component wear and failure.

- Optimize system efficiency: Keep the UPS operating at peak efficiency, which can help manage energy costs.

- Comply with warranty requirements: Many manufacturers require regular maintenance as a condition of their warranty.

Recommended Maintenance Frequency for UPS systems

The frequency of UPS maintenance can vary based on several factors, including the model, capacity, environment, and age of the system.The UPS manufacturers recommendations must be followed to ensure effective performance. This will typically include:

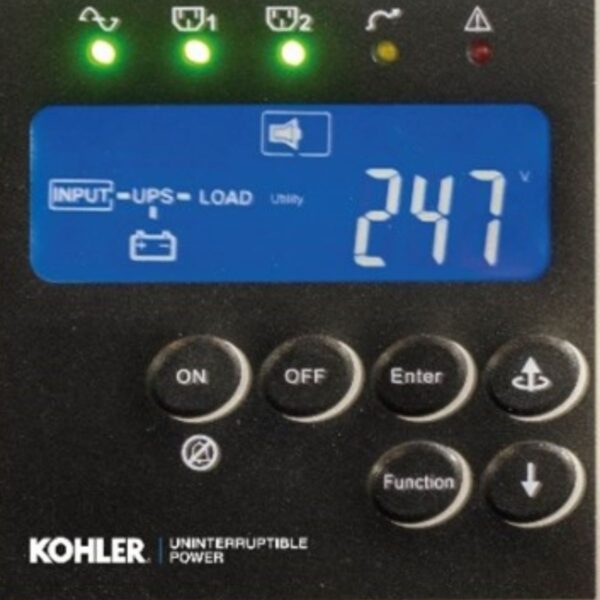

- Daily/Weekly Checks – Basic visual inspections to check for any obvious signs of wear or distress. These checks can be performed by on-site personnel and include looking for warning lights on the panel, ensuring the environment around the UPS is clean and dust-free, and verifying that there are no audible alarms.

- Preventive Maintenance: Comprehensive preventive maintenance should be performed twice a year, depending on the UPS’s complexity and usage. This maintenance includes a thorough check of all mechanical and electrical components, firmware updates, and calibration of critical sensors and alarms.

Critical Components to Monitor

- Batteries: Since batteries are a critical component of UPS systems, they require particular attention. Battery inspections should be carried out every 6 months to check for corrosion, swelling or leakage. It’s also important to test the battery’s voltage and load capacity and assessing the overall health of the battery. Depending on the type, UPS batteries will need replacing when the service life has been reached.

- Capacitors: Capacitors typically have a lifespan of 5 years and are crucial for the stable operation of UPS systems. They should be inspected regularly and replaced according to the manufacturer’s recommendations or if they show signs of degradation.

- Fans: UPS systems rely on fans for cooling and so should be inspected annually to ensure they are not obstructed and are functioning correctly.

- Firmware: Updating the UPS firmware can enhance its functionality and capability, ensuring the system is equipped to handle the latest challenges.

Environment Considerations

The operating environment can significantly affect the maintenance needs of a UPS system. High temperatures, humidity, and dust can lead to more frequent maintenance requirements and premature failure. Ensuring a clean, cool, and dry environment can help in reducing these needs and prolonging the life of the system.

Best Practices for UPS Maintenance

To maximise the reliability and efficiency of a UPS system, consider the following best practices:

- Keep a Maintenance Log: Document all inspections, tests, and maintenance activities. This historical data can help diagnose future issues and optimize the maintenance schedule. (Do we mention KUP Service Logs here?)

- Use Qualified Technicians: Ensure that maintenance is performed by certified professionals who are authorised and have access to the manufacturers recommendations, service news and spare parts. Kohler Uninterruptible Power have a highly experienced team of trained and professional Service Engineers who can service and replace batteries, fans and capacitors for a range of UPS systems, emergency lighting inverters and generators. Get in touch with our team to find out more.

- Follow Manufacturer’s Guidelines: Adhere to the maintenance schedule and procedures recommended by the UPS manufacturer.

Conclusion

Regular maintenance is crucial for the longevity and efficacy of UPS systems. By adhering to a structured maintenance schedule and following best practices, businesses can ensure that their UPS systems provide reliable power protection, maintaining operational continuity and safeguarding valuable data and equipment against unexpected power disturbances.

Register

We are holding a free one-hour CIBSE CPD webinar on best practices for maintaining UPS systems on Tuesday April 29th 2025. Register for your free space now.

Get in touch

Get in touch with our team today for more information on how we can help you to maintain your UPS systems. We can be reached via our Contact Us page or via email.