Sourced from a variety of high-quality manufacturers, modern VRLA batteries are environmentally friendly and safer than earlier open-vented types. This is because today’s VRLA batteries are around 98% recyclable, with well developed recycling infrastructure in most developed countries such as the reputable, trusted partners KOHLER Uninterruptible Power works with.

Unlike earlier open vented cells that needed regular topping up, today’s batteries are sealed units that require no user maintenance, though for maximum resilience inspection and periodic testing by qualified service engineers is recommended. A valve allows venting of gases generated in emergency/over-pressure situations, though the amount given off is so small that it can normally be handled by standard air handling equipment used to control temperature. On this point, it is important to note that as a device based on temperature-dependent chemical reactions, VRLA batteries require a temperature-controlled environment. The best balance between operating performance and lifetime is achieved at 20 deg C. As a rule of thumb, for every 10 deg C above this the working life will halve. The useful working life of the battery is also affected by how the battery is used, so great care must be taken when selecting and sizing batteries for a UPS installation.

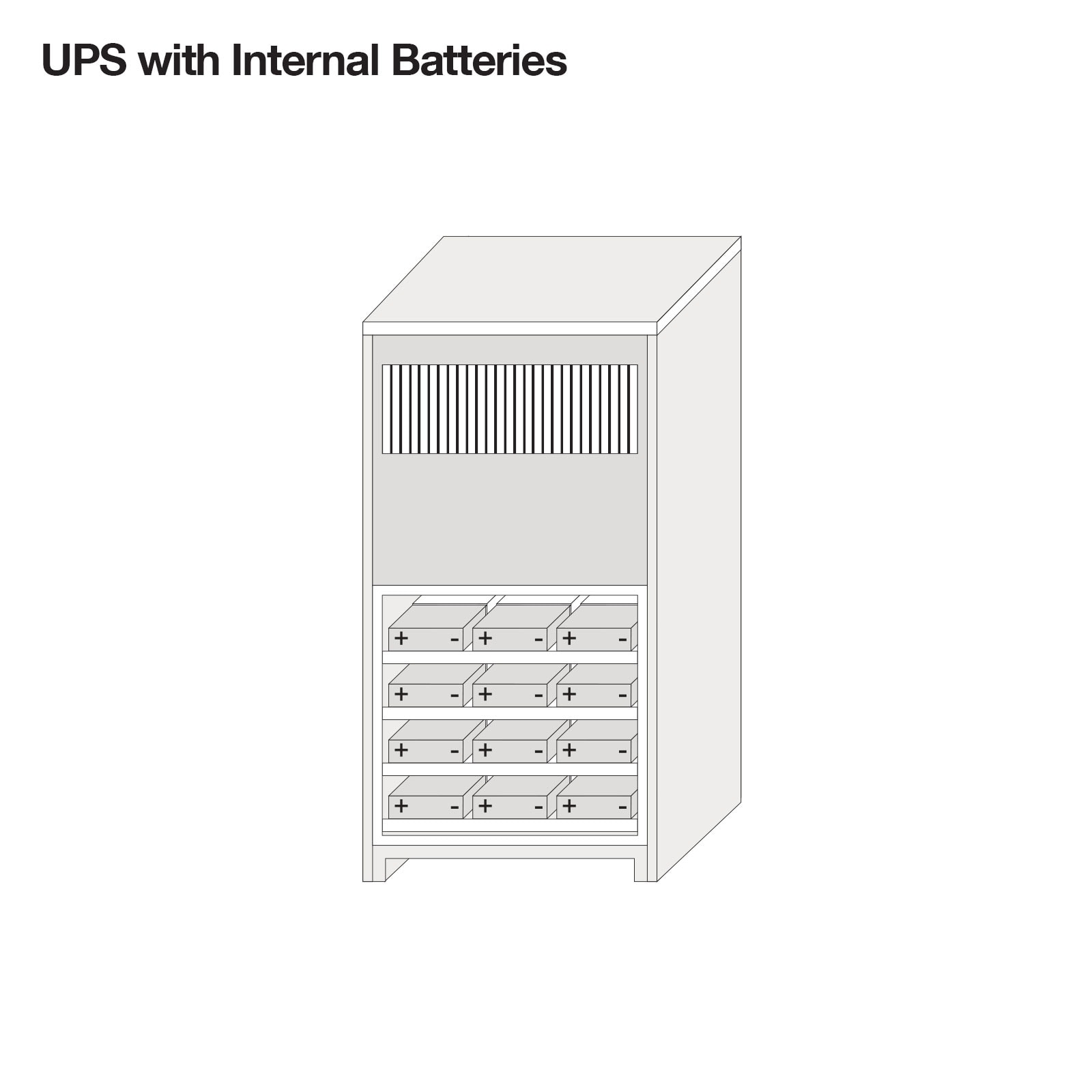

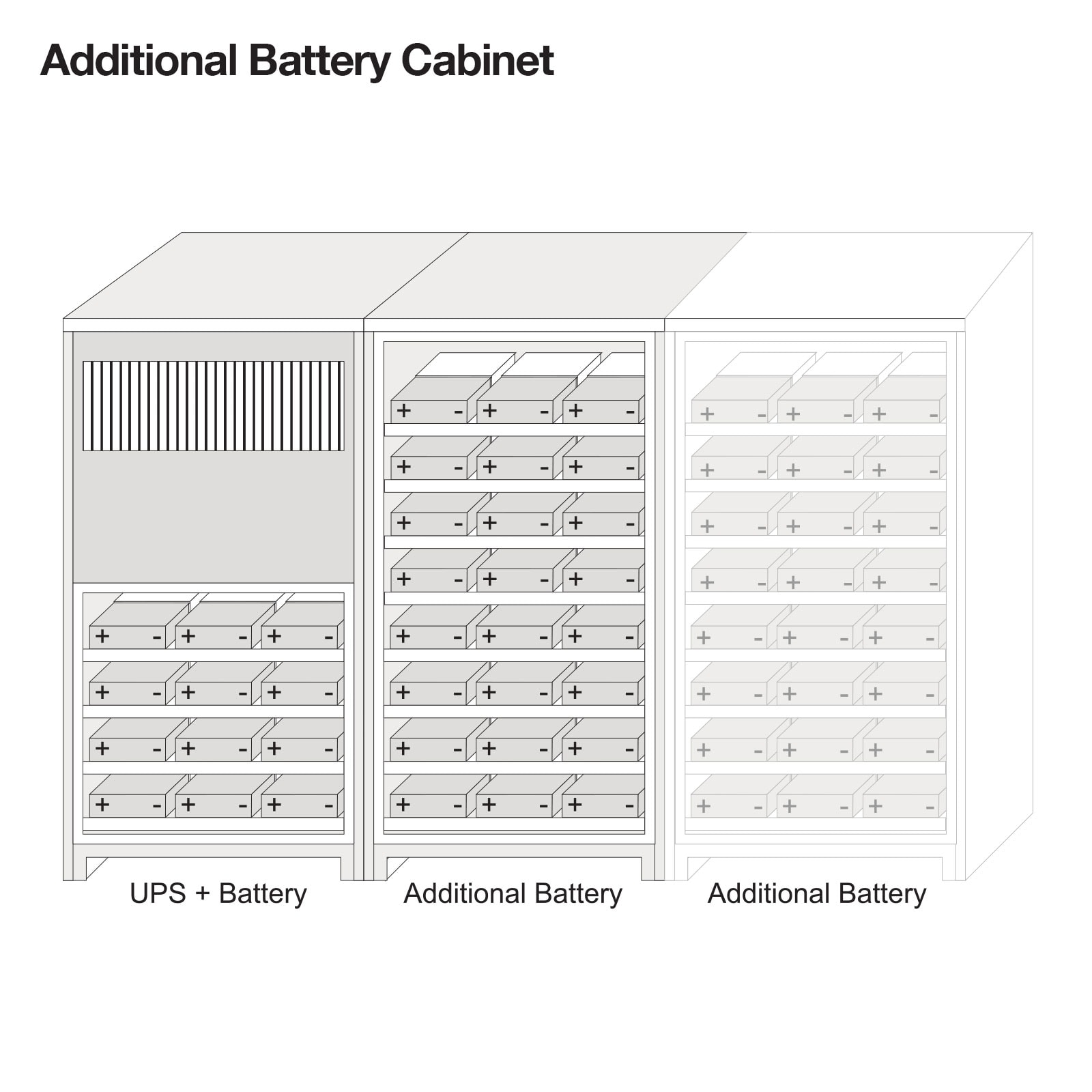

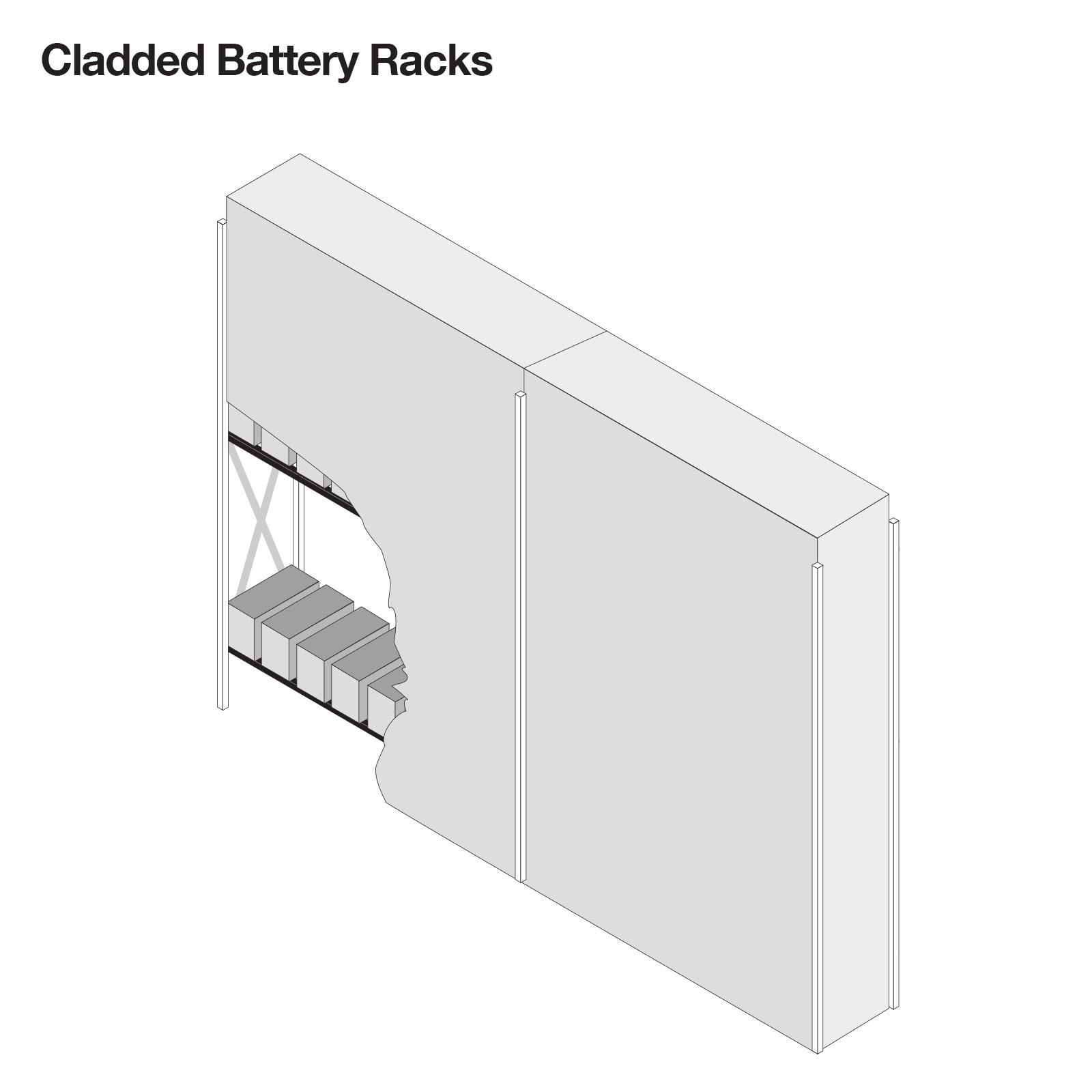

VRLA batteries can be housed in cabinets alongside the UPSs rather than in separate battery rooms, even if the UPSs are operating within an office environment. However, because the combined voltage of the battery system will be the same as a mains electricity supply, for safety reasons it should be protected from unauthorised or accidental contact.

All batteries should be regularly checked or a fixed battery monitoring system should be used. Eventually, they will require replacement, however, this life can be maximised by taking care to operate within a well-managed environment and setting up a regular maintenance schedule. An active battery management system that balances charging between battery “blocks” will potentially increase lifetime by up to 30%.

A VRLA battery block is a number of cells connected together with a given voltage and capacity, where. the capacity is defined in terms of Ampere hours (Ah). The more cells the higher the battery voltage and the larger the plates the higher the battery capacity.

Batteries are generally made in 12-volt blocks using six cells but are also available in 6-volt (three cell), 4-volt (two cell) and 2-volt (single cell) blocks. In the battery configuration, all the cells used in a serial string must be identical to each other. KUP’s expert team have a wealth of experience and a variety of specialised planning tools to help them offer you a solution that perfectly meets your voltage, autonomy and space requirements.

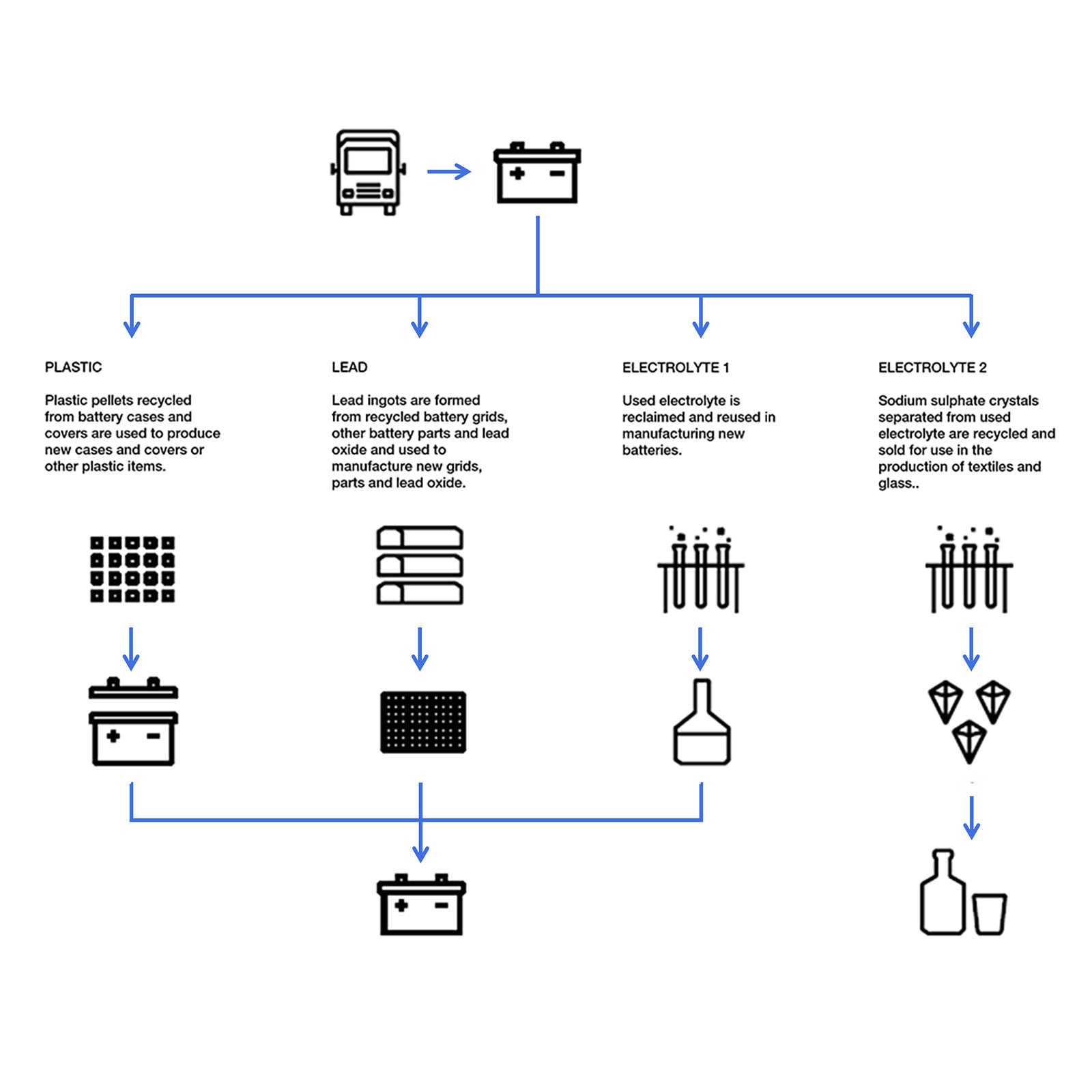

Disposal/Recycling

When a battery has reached the end of its useful working life it must be returned to the point of sale or to a licensed battery dealer for recycling. ‘Old’ batteries are classified as ‘hazardous waste’ and must be disposed of in line with current legislation. KOHLER Uninterruptible Power can assist with the disposing/recycling of VRLA batteries. There is a well-established infrastructure to recycle approximately 98% of the content of end-of-life VRLA batteries into new batteries, plastic items and chemicals used in the glass and textiles industries (see diagram).